Vertical Ribbon Blender

This can replace the popular horizontal ribbon blender in most application. Being a vertical equipment the gravitational force aids in the mixing operation and hence the ratio of 'the area of the mixing element' to the 'operating volume ' is less and hence reduced power requirement for the same throughput. Added advantage is that discharge of the end product is end total.

This can replace the popular horizontal ribbon blender in most application. Being a vertical equipment the gravitational force aids in the mixing operation and hence the ratio of 'the area of the mixing element' to the 'operating volume ' is less and hence reduced power requirement for the same throughput. Added advantage is that discharge of the end product is end total.

one multinational company, apart from manufacturing various products is also into manufacturing one brand of water filter. This water filter has a carbon cartridge which is used as the filter medium. The manufacture of the carbon cartridge involves the following operation:

A] Mixing carbon granules with water and one binder.

B] Molding into required shape and

C] Baking.

One important point in the operation was that the carbon granules should not break or get reduced in size due to any attrition in the mixer as this will affect the filtration area.

For mixing operation, the client was using a machine called 'coating pan 'which is normally used in pharmaceutical companies for tablet coating application. This machine consists of a truncated spherical pan with an open top and the bottom slightly flat. This pan rotates around an axis which is inclined to the vertical. Also supported form the center is stationery. Scraper arrangement which is expected to ensure effective mixing .

TRAXIT was called upon to scale up the equipment to double the production. On studying the operation, following drawbacks were observed in the system:

1 As the bowl is rotating, the top does not have a fixed cover as a result when water is added to the carbon granules, there is dusting,

2 when the binder is added, the product rotates as a mass and no mixing taken place. To affect mixing, bowl had to be manually tilted forward and backward which was rather cumbersome.

3 After the mixing was over, the container again had to be tilted to unload the mixture. Even with this, complete product could not be unloaded as there was a limitation on the extent to which the bowl could be tilted , as a result , part of mixture had to be scooped out , which again was time consuming and also cumbersome .

On studying the above operations TRAXIT suggested the use of TRAXIT vertical ribbon blender. With the use of vertical ribbon blender, all the drawbacks highlighted were eliminated

Our Products

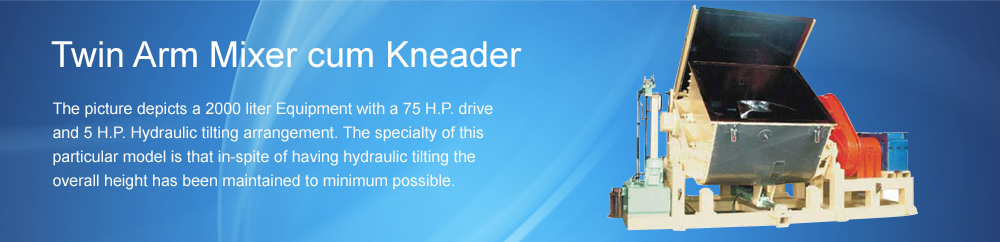

- Twin Arm Mixer cum Kneader

- Tailor Made Planetary Mixers

- Contra Mixer

- Rubber Cutter Dissolver

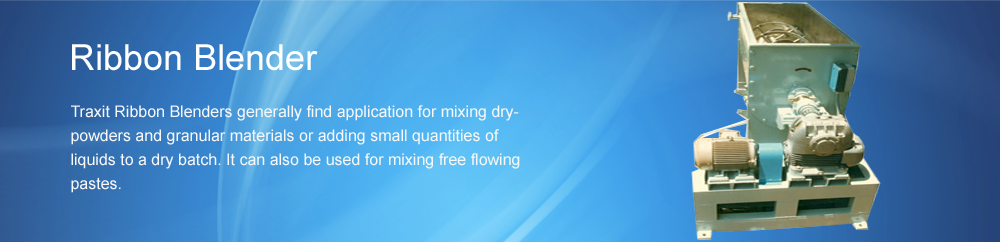

- Ribbon Blender

- Ploughshare Mixers

- "V" Blender

- Vertical Rotary Air Lock

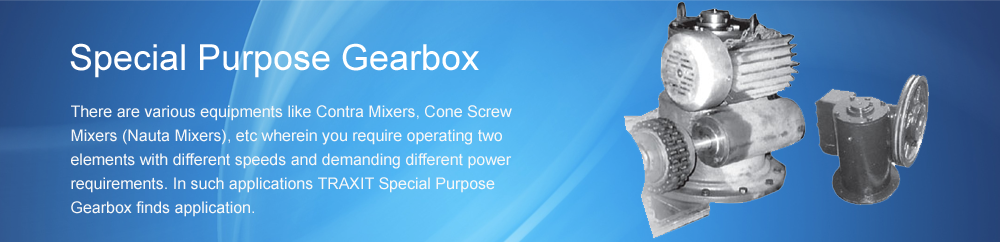

- Special Purpose Gearbox

- TEPL Lube Applicator

- Vertical Ribbon Blender

- Continuous Kneader

- Vacuum Double Planetary Mixer

- Schredder

- Disperser

- Cone Screw Mixer

- MFB Mixer